UPVC Screw Fastening Machine

Warranty: 2 years

Voltage: To be negotiated, customize according to needs

UPVC Window Making Machines

UPVC Window Screwdriver Machine

Automatic screw fastening machine for UPVC window frames

Features

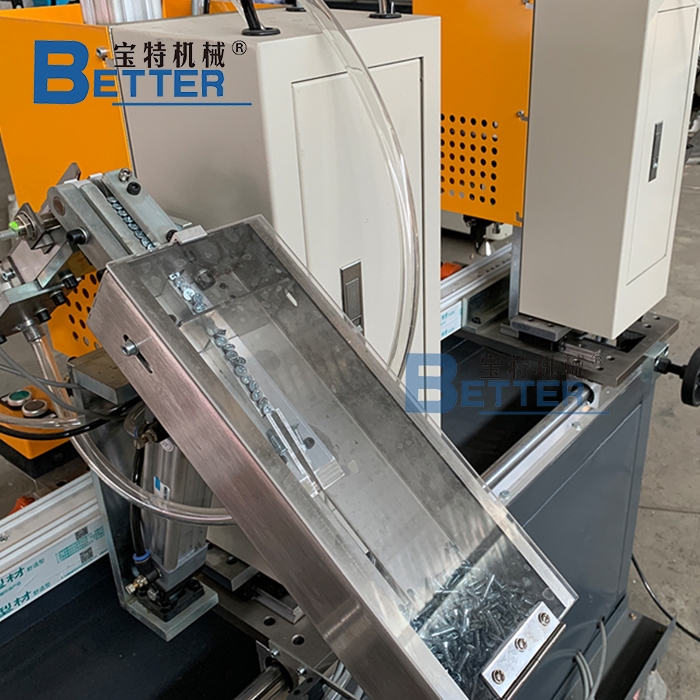

The UPVC Screw Fastening Machine is a specialized device designed to insert and fasten screws into UPVC window and door profiles with speed, accuracy, and consistency. And it is commonly used for securing reinforcement steel inside profiles, which is essential for enhancing structural strength and stability.

- Application: It is used for automatically connectingprofiles and steel reinforcements by press foot switch without drilling.

- High-Torque Electric Motor: Equipped with a high-torque electric motor with overload protection to avoid instability caused by excessive air consumption when using air motors.

- Automatic Feeding: Simplifies operation with automatic nail feeding for high efficiency.

- Automatic Profile Height Adjustment: Automatically adapts to different profile heights without the need for adjustment when changing profiles.

- Quick Nail Ejection: Features a quick nail ejection system, enabling fast discharge of nails in case of a failed fastening attempt.

- Quick-Change Fastening Rod: Change the rod in just 10 seconds for easy maintenance.

- Models: Single Head UPVC Screw Fastening Machine, Double Head UPVC Window Screw Machine, Three Head UPVC Window Screwdriver Machine, Four Head UPVC Frame Screw Fastening Machine, as well as CNC Model Types

Video

https://youtube.com/shorts/YzoshWEnk9A?feature=share

Specifications

| Item | Value |

| Power input | 380V/220V 50Hz, base on request |

| Motor power | 1.5KW |

| Processing height | 0~120mm |

| Processing width | 0~120mm |

| Screw model (Diameter*length) | φ3~φ5 x (13~26) Cross countersunk screw |

| Air pressure | 0.6-0.8MPa |

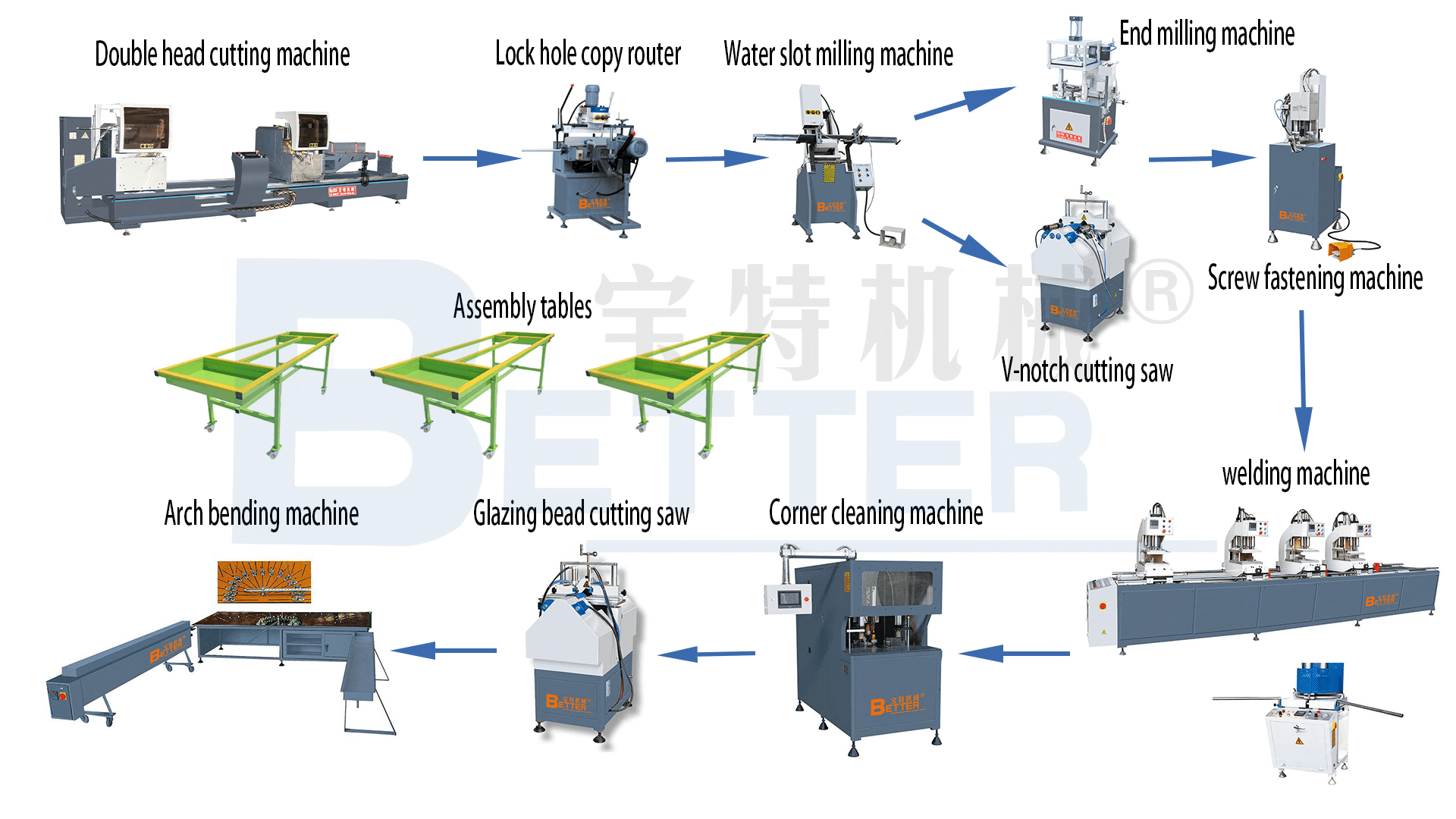

Best Machines for UPVC Window Fabrication

UPVC window manufacturing process

First, cut UPVC profiles to the required sizes using UPVC cutting machine. Next, drill lock holes, drainage slots, and other openings with copy routers and milling machines. After preparing the profiles, move on to mullion processing, using end milling machine or V-notch cutting machine methods to ensure perfect fitting. Then, insert reinforcement steel and fasten it securely with screw fastening machine to strengthen the structure. After reinforcement, UPVC welding machines join the corners of the window frame to form a rigid structure. Once welding is complete, use corner cleaning machine to remove excess material and deliver a smooth, clean finish. Next, bead cutting machine shape the glazing beads that hold the glass securely. For custom designs, arch bending machines form curved profiles as needed. Finally, on the assembly table, install hardware such as handles, locks, and hinges.