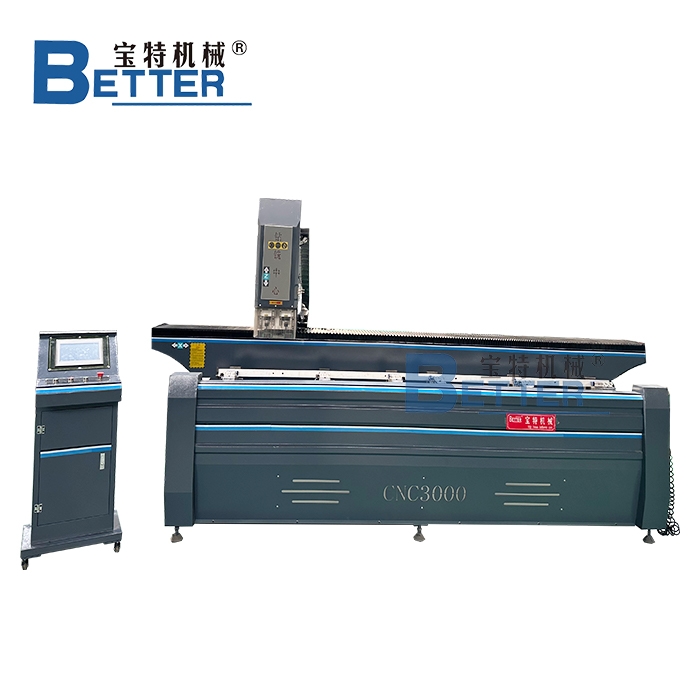

CNC Milling Drilling Machine For Aluminum

Warranty: 2 years

Voltage: To be negotiated, customize according to needs

Other X-way stroke type: 2500mm, 3000mm, 3500mm

CNC Processing Machine For Aluminum Profile With Tool Change Function

Features

The CNC Milling Drilling Machine for Aluminum Profiles delivers precise and efficient machining for various industrial level processing requirements. With an automatic tool changer (ATC) , the machine quickly switches tools during multi-step operations—eliminating downtime and boosting productivity. Intelligent CNC control system, it performs drilling, slotting, milling, and tapping tasks in one seamless workflow. Moreover, the machine features a heavy-duty structure that ensures stability even at high speeds. Operators can easily program and monitor jobs through the user-friendly interface, which shortens the learning curve and minimizes errors. Ideal for aluminum profile processing manufacturers, this CNC solution increases throughput while maintaining high levels of precision and repeatability.

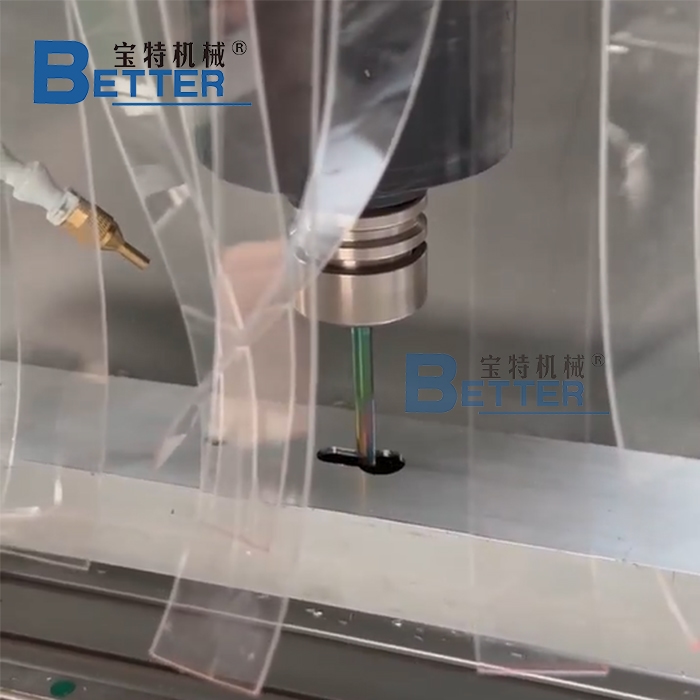

- Application: Industrial level aluminium CNC Milling Drilling Machine with tool automatic change function.It is suitable for milling, drilling and tapping aluminum alloy profile, aluminum wood composite profile, copper profile and uPVC profile.

- 3 surface processing: The workbench can rotate to achieve 0° 90° and -90° three surfaces milling of the profile at one time clamping.

- CAD drawing import: It is able to insert DFX version drawing if needed.

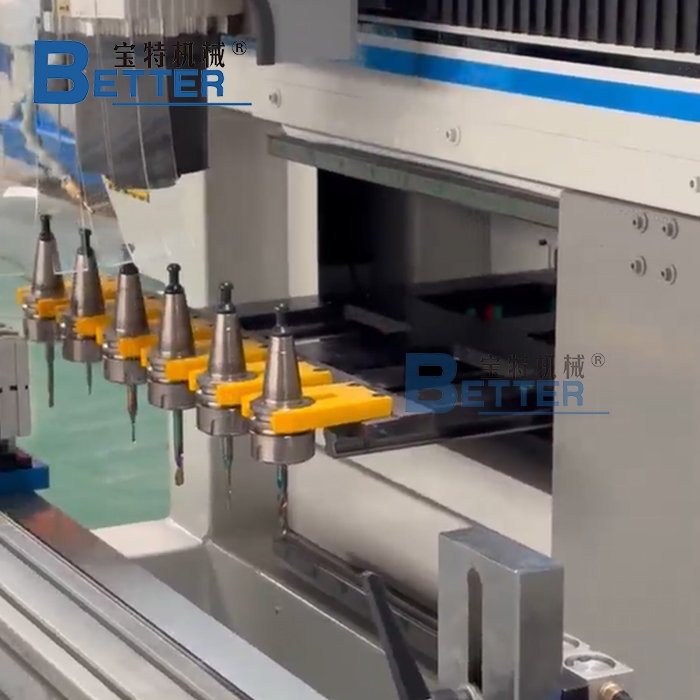

- Automatic Tool Change: Six tool sites in the library, no need to change the tools manually during processing, greatly improve the operation efficiency.

- CNC control system: Equipped with an industrial-grade computer system with hundreds of shapes inside the system, easy to operate and program, friendly man-machine interface.

- High-precision Motion System: Equipped with a high-precision linear guide rail pair and ball screw, ensures smooth operation, minimizes friction, and enhances stability, provides exceptional positioning accuracy and processing precision, resulting in high-quality performance and reliable machining outcomes.

- Automatic spray system: Automatic spray device effectively extends the tool life and ensures the cleanliness of the processing surface.

- Pneumatic clamping system: Equipped with horizontal pneumatic clamping devices, suitable for firmly fixing a wider range of profile, ensures processing accuracy.

- Sturdy body: Adopts advanced steel structure design, enhances the stability of the structure, extends the service life of the equipment, and prevents deformation.

- Options: One head model, various X-way model, no tool change model.

Specifications

| Model | LZX3A-CNC-1800/2500/3000/3500 |

| Power input | Base on request |

| Motor power | 5.5KW |

| Motor rotation speed | 18000 r/min |

| X-way stroke | 1800mm/2500mm/3000mm/3500mm |

| Y-way stroke | 0-150mm |

| Z-way stroke | 0-150mm |

| Air pressure | 0.6-0.8Mpa |

Video

https://youtube.com/shorts/PUVbPv08_3M?si=PlZjXh7S7POXyHrj

Package & Delivery

- FCL: plastic rolling wrap + shipping container

- LCL: plastic rolling wrap + plywood case package

Our Company

Jinan Better Machinery Co., Ltd. is a leading manufacturer specializing in the research, development, and production of equipment for upvc and aluminum doors and windows, aluminum processing machine, as well as insulating glass processing machinery.