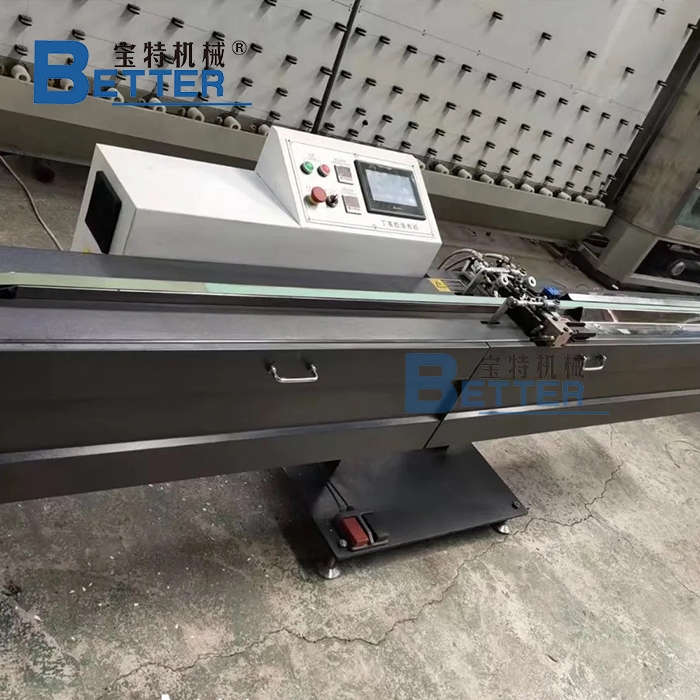

Butyl Extruder Machine

Warranty: 2 years

Voltage: 380V 50hz 3Phase, or base on request

Butyl Coating Machine

Butyl Sealant Coating Machine

Automatic Butyl Extruder for Insulating Glass Production

Features

The Butyl Extruder Machine plays a crucial role in the insulating glass production process, as it precisely applies butyl sealant to aluminum spacer frames. To ensure consistent performance, the machine integrates automatic temperature control along with an adjustable coating thickness system. As a result, it delivers a uniform sealant layer that enhances both adhesion and air-tight sealing—key factors for improving the thermal insulation and longevity of insulating glass units. Moreover, with its precision-engineered nozzles and stable extrusion system, the machine boosts production efficiency while minimizing material waste. Therefore, it serves as an ideal solution for manufacturers producing energy-efficient UPVC and aluminum windows as well as curtain walls.

- Application: This machine is specially designed for applying butyl sealant to aluminum spacer frames in insulating glass production. It ensures accurate, efficient, and adjustable sealant coating for optimal energy-saving performance.

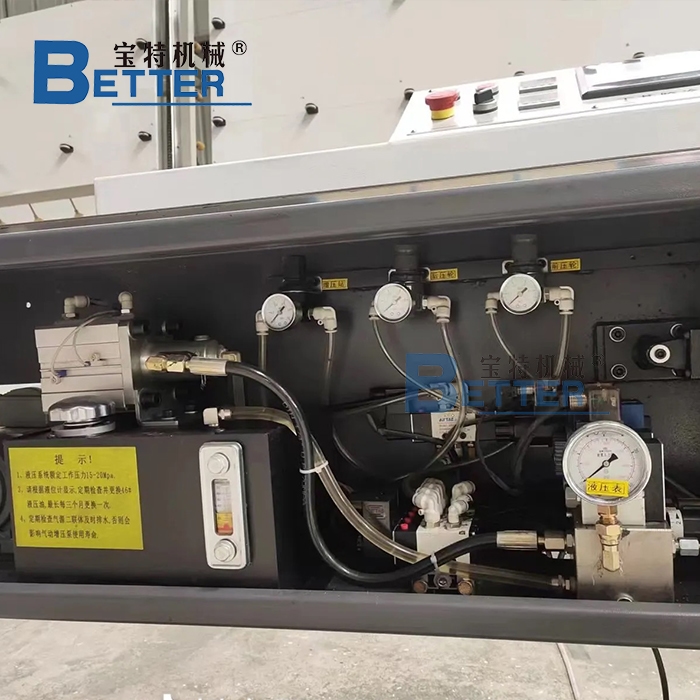

- Stable Pressure Output: Equipped with an advanced pneumatic pump system, ensures stable pressure while significantly improving energy efficiency.

- User-Friendly Interface: The intelligent touchscreen HMI (Human-Machine Interface) provides a clear display and easy operation, reducing user learning time and improving workflow efficiency.

- Variable Speed Control: With an inverter-controlled conveyor system, the working speed can be adjusted from 2 to 45 meters per minute across five selectable levels, meeting diverse production requirements.

- Adjustable Coating Width: The advanced automatic glue width adjustment system allows precise control from 6mm to 18.5mm, ensuring high accuracy across different frame sizes.

- Rotating Glue Tank Design: The glue cylinder adopts a rotary structure, which is free to rotate, release glue, and maintenance is more convenient, simplifying glue filling, dispensing, and daily maintenance.

- Large Glue Tank Capacity: The oversized glue cylinder supports a single refill of up to 14kg of butyl, enabling long continuous operation and reducing downtime.

Video

https://youtube.com/shorts/JY1rvsW2VKQ?feature=share

Specifications

| Item | Value |

| Power input | 380V/220V 50Hz, base on request |

| Motor power | 3KW |

| Air pressure | 0.5~0.8MPa |

| Glue extrusion pressure | 10-20Mpa |

| Conveying speed | 2-45m/min |

| Butyl mouth distance | 4-27mm |

| Glue temperature | 110-160℃ |

| Machine size | 3000*700*1100mm |

Other Related Insulating Glass Production Machines

- Insulating Glass Production Line

- Automatic Aluminum Spacer Bar Bending Machine

- Horizontal Glass Washing Machine

- Insulating Glass Machines

- Aluminum Window Machines

- UPVC Window Machines