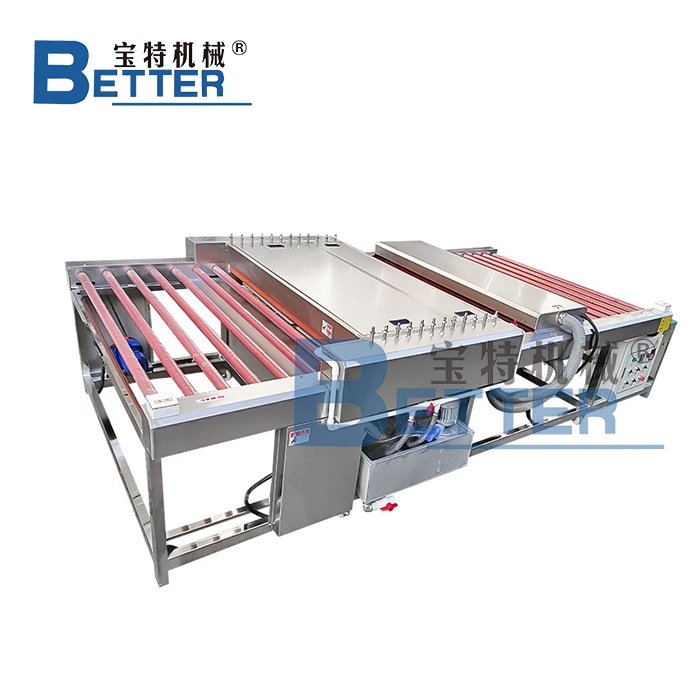

Window Glass Washing Machine

Warranty: 2 years

Voltage: To be negotiated, customize according to needs

Glass cleaning machine for UPVC window production

Automatic glass washing machine for double glazing

Insulating glass washing and drying machine

Features

The Window Glass Washing Machine efficiently cleans and dries glass used in UPVC and aluminum windows and doors. With durable nylon brushes, high-quality sponge rollers, and a built-in hot air drying system, it consistently delivers spotless and dry surfaces. As a result, manufacturers can streamline their production process while ensuring high-quality output. Moreover, its simple operation and stable performance make it an ideal choice for those looking to improve glass cleaning in window and door assembly lines.

- Application: Window Glass Washing Machine is a vital piece of equipment in UPVC & aluminum window production lines, to clean and dry flat glass efficiently.

- Three Sets of High-Quality Nylon Brushes: Effectively remove dust, oil, and residues without scratching the glass surface.

- Two Sets of Water-Absorbing Sponge Rollers: Efficiently absorb residual water from the glass surface before entering the drying section, ensuring spot-free results.

- Stainless Steel Structure with Anti-Corrosion Design: Durable, rust-resistant frame ideal for continuous production environments and extended machine lifespan.

- Adjustable Speed Control: Conveyor speed can be adjusted to match different glass sizes and production lines, enhancing flexibility.

- Hot Air Drying System: Ensures rapid and complete drying after cleaning.

- Compatibility with Insulated Glass & Window Glass: Suitable for both standard and insulated (double glazing) glass, widely used in window and door manufacturing.

- Optional Customized Configuration: Machine can be tailored with extra brushes, special conveyors, or size extensions based on requirements.

- Options: Vertical Double Glazing Glass Washing Machine

Video

https://youtube.com/shorts/RU4AyH81dKY?feature=share

Specifications

| Item | Value |

| Power input | 380V 50HZ 3P, base on request |

| Motor power | 10KW |

| Minimum washing size | 200*200mm |

| Maximum washing size | 1600*2000mm |

| Machine size | 3000*2000*1100mm |

| Weight | 800KG |

Insulating Glass Production Flow & Required Machines

To produce high-quality insulating glass units (IGUs), manufacturers follow a structured process using several essential machines. First, the raw glass is precisely cut using a glass cutting machine. Then, an edge polishing machine smooths the glass edges for a clean finish. After that, a glass washing machine thoroughly cleans the glass surface to ensure perfect adhesion.

Next, the aluminum spacer bar is shaped with a bar bending machine and filled with desiccant using a desiccant filling machine, which helps prevent internal fogging. Following this, a butyl extruder machine applies the primary sealant.

Once the spacer is accurately aligned between the two glass panels, a Double Group Sealant Extruder adds the secondary sealant for airtight bonding. Finally, if enhanced insulation is needed, an Insulating Glass Aerator injects inert gas into the unit. If you want to improve the level of automation, insulating glass production line can also be used to subsitute some machines, such as glass washing machine and double group sealant extruder. Altogether, this streamlined process ensures strong, energy-efficient insulating glass—ideal for both UPVC windows and aluminum window systems.