Thermal Break Crimping Machine

Warranty: 2 years

Voltage: To be negotiated, customize according to needs

Thermal Break Rolling Machine

Thermal Break Assembly Machine

Thermal Break Window Machine

Energy-saving Aluminum Window Production Line

Thermal Break Crimping Machine – Thermal insulation aluminum profile equipment

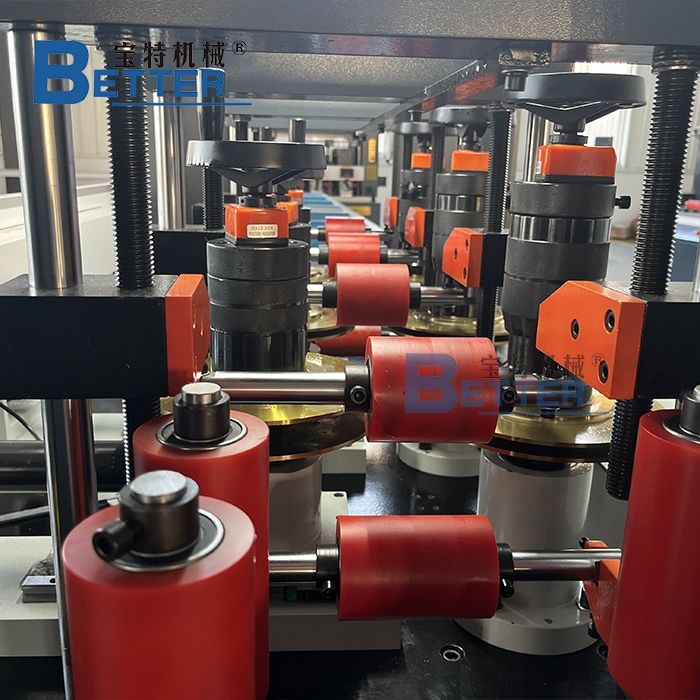

The Thermal Break Crimping Machine is essential for assembling thermal break aluminum profiles with precision and strength. Designed for energy-efficient window and door systems, this machine seamlessly joins aluminum profiles and polyamide strips. With its adjustable rollers and intuitive controls, it supports various profile types and sizes, operators can quickly switch between profile types, ensuring consistent quality across batches. Whether for curtain wall systems or architectural framing, the Thermal Break Crimping Machine ensures accurate alignment and a strong mechanical bond. This reliable solution helps manufacturers improve productivity and meet modern insulation standards with confidence.

- Triple Roller Sets: Three groups of precision rollers (6 blades total) deliver strong, consistent pressure to bond aluminum profiles with thermal insulation strips securely.

- Real-Time Pressure Monitoring: Digital sensors track rolling pressure across all three zones, ensuring accuracy and preventing profile deformation.

- Independent Roller Adjustment: Adjust each roller group separately to switch quickly between different profile sizes and insulation strip heights.

- Nylon Rollers: High-quality nylon rollers run smoothly and protect profile surfaces from scratches during crimping.

- User-Friendly Operation: Simple controls and fast setup streamline training and boost efficiency in both small and large-scale production.

Video

Specifications

| Item | Value |

| Power input | 380V/220V 50Hz, base on request |

| Motor power | 2.2KW |

| Roller disc diameter | φ238 |

| Height adjustment range | 8-60mm |

| Maximum profile size | 280*230mm |

| Machine size | 1220*1300*1350mm |

| Weight | 800KG |

Related Machines & Options

- Thermal break knurling machine

- CNC Thermal break assembly machines

- Aluminum CNC double head cutting machine

The Advantage of Thermal Break Aluminum Profiles

Thermal break aluminum profiles offer outstanding energy efficiency by reducing heat transfer between the interior and exterior of a building. By inserting a polyamide insulating strip between two aluminum profiles, these advanced systems significantly improve insulation performance, helping to maintain indoor temperatures and reduce energy costs. Moreover, they prevent condensation and enhance sound insulation, creating a more comfortable living or working environment. In addition to thermal benefits, thermal break profiles also maintain excellent structural strength and weather resistance, making them ideal for modern window and door systems. With rising demands for energy-saving construction, thermal break aluminum profiles provide a smart, sustainable solution without compromising durability or aesthetics.