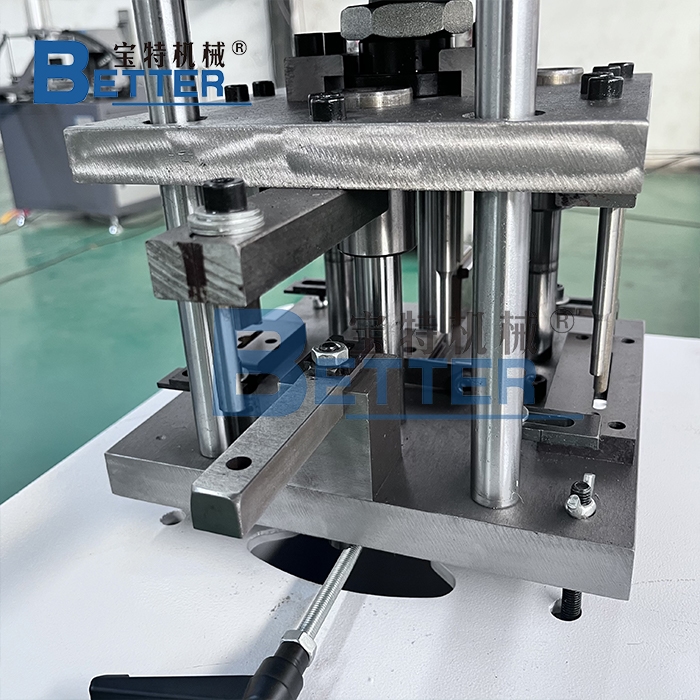

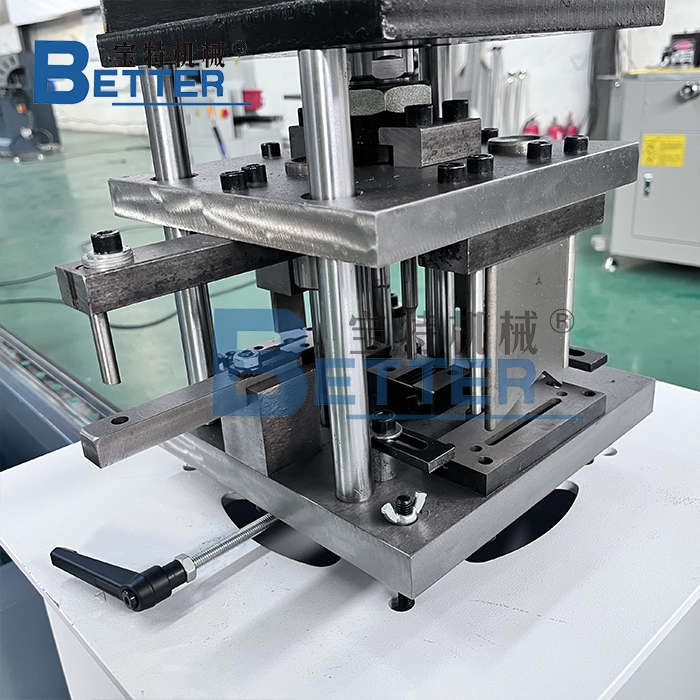

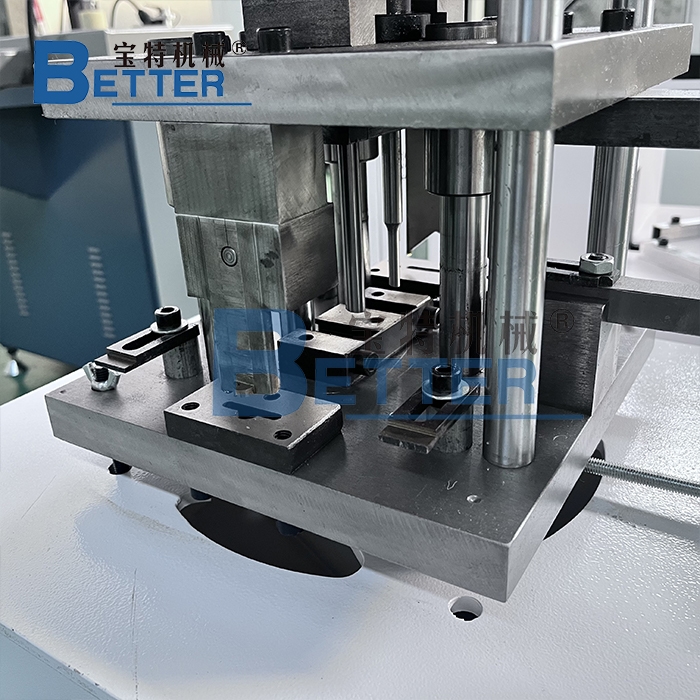

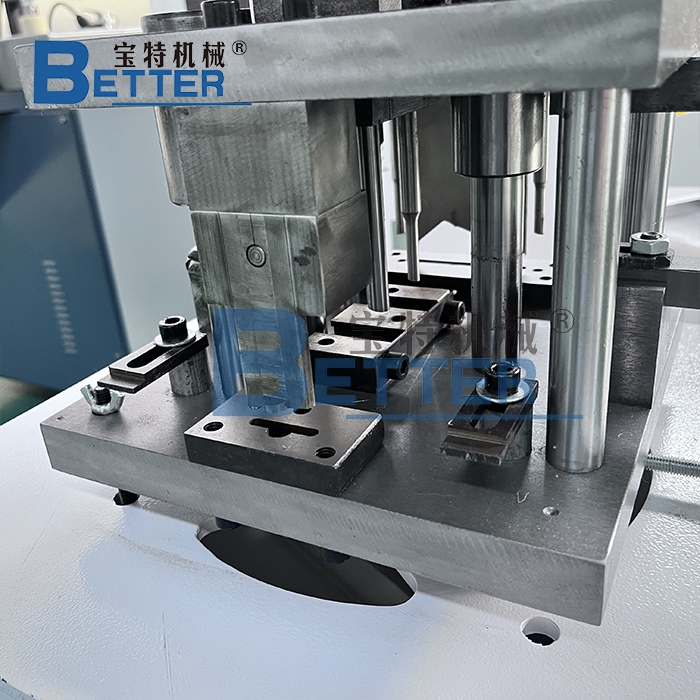

Pneumatic Aluminum Profile Punching Machine

Warranty: 2 years

Pneumatic punching type

Window and Door Punching Machine

Aluminum Profile Press Punching Machine

Aluminum Window Making Machines

Feature

The Pneumatic Aluminum Profile Punching Machine offers a high-efficiency solution for precise punching of both aluminum window and door profiles, and UPVC profiles. Driven by a reliable pneumatic system, it delivers fast, accurate results while remaining energy-efficient and low-maintenance. Widely applied in the production of sliding windows, casement doors, and curtain wall systems, this machine meets various punching demands with ease. Thanks to its rotating head design, operators can quickly switch interchangeable dies to punch press different holes—minimizing downtime and maximizing output.

- Application: It is used for punching various holes of aluminium and uPVC windows.

- 5 standard molds: The machine is equipped with standard 5 molds to punch casement stay holes, lock holes, water slots, and handle holes.

- Pneumatic drive: Pneumatic foot valve control ensures stable operation.

- Fast operation: Greatly reduce the time of making holes, highly improve the productivity.

- Options: Hydraulic punching machine, single head aluminium punching press, double column aluminum window punching machine

Video

https://youtube.com/shorts/2oJWmE8-G34?feature=share

Specifications

| Item | Value |

| Air pressure | 0.6~0.8MPa |

| Punching travel | 50mm |

| Machine size | 600*600*1550mm |

| Weight | 180KG |

Aluminum Window Production

The pneumatic aluminum profile punching machine dramatically improves the efficiency of window and door production by delivering fast and precise punching results. To complete the entire fabrication process seamlessly, manufacturers also rely on several essential machines—including double head aluminum cutting machine / single head aluminum cutting machine, CNC end milling machines, CNC copy routing machines, and crimping machines. Working in harmony, these machines create a smooth and accurate production flow from initial profile cutting to final assembly. Whether you’re upgrading your current setup or starting a new line, we’re ready to provide tailored solutions and expert guidance. Get in touch with us anytime—we’re here to support your success!