Automatic Desiccant Filling Machine For Insulating Glass

Warranty: 2 years

Voltage: To be negotiated, customize according to needs

Molecular Sieve Filling Machine

Spacer Bar Desiccant Filler

Automatic Desiccant Filling Machine

Features

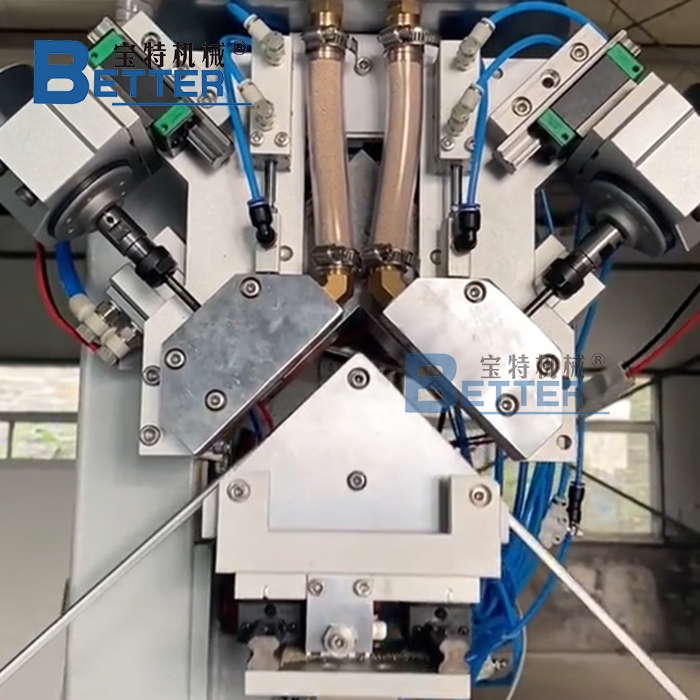

The Automatic Desiccant Filling Machine For Insulating Glass is an essential solution for efficiently filling desiccant into aluminum spacer bars. Designed for IGU production lines, this machine helps maintain the long-term clarity and performance of insulating glass by ensuring proper moisture control. It offers fast operation, consistent filling quality, and simple controls, making it suitable for both large-scale and small-scale glass processing workshops. With reliable automation, the machine reduces manual labor and increases production efficiency. Whether you’re producing standard or high-performance double glazing units, this desiccant filling machine helps streamline the process and ensures lasting durability in IGU systems.

- Application: This machine is specially designed for efficiently and precisely filling desiccant into aluminum spacer frames used in insulating glass units (IGUs), ensuring optimal moisture absorption and long-term glass clarity.

- Adjustable Filling Height:The filling height can be freely and precisely adjusted to accommodate a wide range of aluminum spacer bar sizes, ensuring optimal compatibility across different insulating glass production requirements.

- Advanced Feeding System: Incorporates a high-performance gas-fluid dynamics feeding device, which ensures smooth and consistent desiccant flow without clogging.

- Auto Refill Function: Features an automatic refill system that prevents underfilling and ensures every spacer frame is packed with the right amount of desiccant.

- Back Drilling Capability: Supports back-drilling of the spacer bar, allowing for the filling of larger desiccant beads and improved filling efficiency.

- Height-Adjustable Structure:Equipped with a lift-adjustable frame, making it easier to adapt to different operator heights and spacer bar dimensions, improving overall ease of use and ergonomics.

Video

https://youtube.com/shorts/2py3jayANuU?feature=share

Specifications

| Item | Value |

| Power input | 220V 50Hz Single Phase, base on request |

| Specification of Aluminum Bar | Min.250×250mm; Max.2000×2000mm |

| Width of Aluminum Bar | 5.5-26.5mm |

| Air Pressure | 0.5~0.8Mpa |

| Diameter | ≤0.5mm |

| Filling Speed | 5-10s/piece |

| Filling Size | Min.200×280mm; Max.2000×2000mm |

| Machine size | 1500*850*4000mm |

How to Make Double-Glazed Windows?

To make double-glazed windows, manufacturers follow a precise and efficient process using specialized machines. First, cutting glass sheets to size using a glass cutting machine. Then, preparing the aluminum spacer frames with a bending machine and fill them with desiccant using an automatic desiccant filling machine. After that, applying butyl sealant to the frames using a butyl extruder machine. Once finished all preparations, put the glass sheet on the fully automatic insulating glass production line for double glazing, the line can cleaning and drying glass, press two panels together, then seals the edges automatically, and fills gas if needed. Throughout the process, advanced control systems ensure precision, improve efficiency, and reduce material waste. This streamlined workflow helps produce durable, energy-efficient double-glazed windows that meet modern building standards.