UPVC windows, also known as PVC windows or vinyl windows, are gaining popularity due to their durability, energy efficiency and low maintenance requirements. In this guide, we will walk you through the benefits of UPVC windows, the necessary machinery, production processes and maintenance tips to ensure long-lasting performance.

Advantages of UPVC Windows

When choosing windows, it is important to understand the main benefits of UPVC Windows.

- Durability – UPVC Windows are highly resistant to weather, UV rays, and corrosion. They provide excellent long-term performance without deterioration.

- Energy Efficiency – Moreover, the strong insulation of UPVC helps maintain indoor temperatures. This feature significantly reduces heating and cooling costs.

- Low Maintenance – In addition, UPVC Windows require no painting, polishing, or frequent repairs. They are easy to clean and very reliable over time.

- Soundproofing – Furthermore, UPVC Windows offer excellent noise reduction. They create a quieter and more comfortable living environment, especially in busy areas.

- Eco-Friendly – Lastly, UPVC is a recyclable material. Choosing UPVC Windows supports eco-friendly construction and reduces environmental impact.

Because of these outstanding advantages, many manufacturers now prefer UPVC Windows. To produce them efficiently and accurately, high-quality UPVC Window Machines are essential.

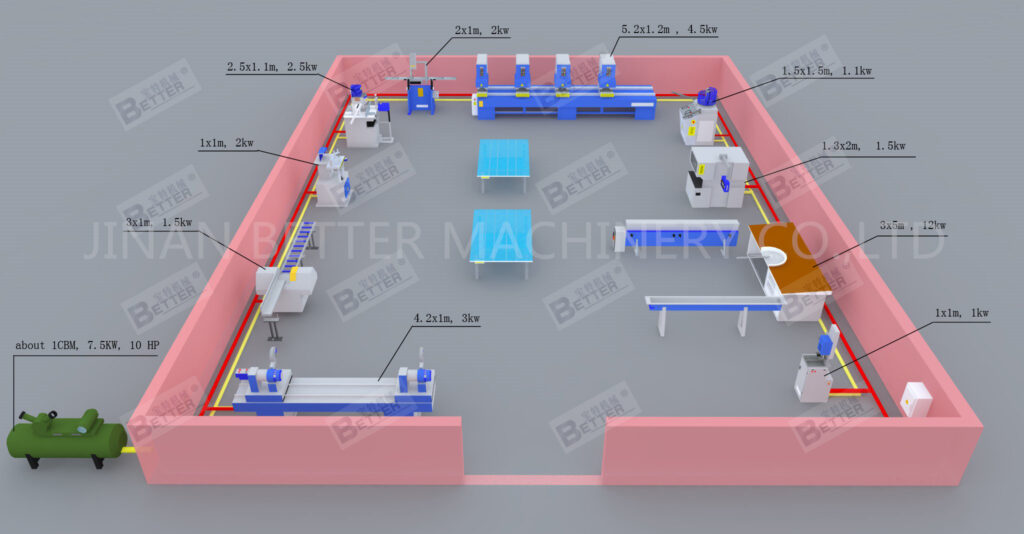

UPVC Window Production Flow & Essential Machines

To manufacture high-quality UPVC Windows, it is crucial to use specialized UPVC Window Machines at every step.

Step 1: Cutting Profiles

First, you need to cut the UPVC profiles to the required sizes.

Cutting Saws are essential for this step. Based on efficiency, you can choose between a single head cutting machine and a double head cutting machine. Moreover, depending on automation level, options include standard cutting saws, digital display cutting machines, and CNC cutting machines. These solutions greatly improve accuracy and production speed.

Step 2: Processing Holes

Next, hole processing is necessary for locks, handles, and drainage.

- Lock Hole Copy Routers, also known as lock hole milling machines, are vital for creating lock holes and installation slots. Depending on your production needs, you can choose between automatic and CNC copy router.

- Additionally, Water Slot Milling Machines help create drainage slots, which are critical for waterproofing and moisture control in UPVC Windows.

Step 3: Mullion Processing

Then, you need to process mullion profiles, and there are two common methods.

- One method uses an End Milling Machine to precisely mill mullion ends for screw-fixed connections. These machines come in manual, automatic, and CNC versions to meet different production requirements.

- Alternatively, a V-notch Cutting Saw cuts a V-shaped notch, allowing the mullion to be seamlessly welded into the frame using a uPVC welding machine.

Step 4: Connecting Reinforcement Steel

After that, steel reinforcements must be inserted to strengthen the profiles.

Screw Fastening Machines are used for this task. You can select from single head, double head, three head, or even four head models based on your production capacity needs.

Step 5: Welding

Welding comes next, and it is a key step in making strong UPVC Windows.

UPVC Welding Machines heat and press the profiles together to form durable joints. You can choose seam welding machines or seamless welding machines, with configurations like single head welding machine, double head welding machine, three head welding machine, or four head upvc welding machine options.

Step 6: Cleaning

After welding, the corners require cleaning for a perfect finish.

Corner Cleaning Machines remove excess welding material. Popular choices include CNC models with 3-cutter, 6-cutter, or even 9-cutter options, helping you achieve a clean, professional appearance.

Step 7: Bead Cutting

Next, you need to cut the glazing beads that secure the glass.

UPVC Bead Cutting Machines accurately cut the beads to the right size. We offer both small and high-efficiency bead cutting machines, ensuring precision and speed in your UPVC Window production line.

Step 8: Arch Bending

If your project requires arched or curved windows, you will need an Arch Bending Machine.

This machine bends UPVC profiles precisely, enabling unique and modern window designs that meet custom architectural requirements.

Step 9: Assembling Doors and Windows

Finally, it is time to assemble the finished UPVC Windows.

Using assembly tables, you can install handles, locks, and hinges. After that, every window goes through strict quality checks to ensure durability, smooth operation, and proper sealing. Once approved, the windows are carefully packed and prepared for delivery.

Maintenance Tips for UPVC Windows

To maximize the lifespan and performance of UPVC windows, regular maintenance is essential. Here are some practical tips:

- Cleaning– Wipe frames and glass with mild soapy water to remove dirt and dust.

- Lubrication– Apply lubricant to hinges and locks to prevent stiffness and ensure smooth operation.

- Seal Inspection– Check rubber seals for any signs of wear and replace if necessary to maintain insulation and waterproofing.

- Glass Care– Use a glass cleaner to keep the window panes clear and free from smudges.

- Regular Checks– Inspect hardware fittings and tighten screws if needed to maintain structural integrity.

Conclusion

In conclusion, manufacturing UPVC Windows involves a clear and structured process designed to ensure high durability, excellent energy efficiency, and minimal maintenance. By using the right UPVC Window Machines and following best production practices, manufacturers can consistently deliver top-quality UPVC Windows that meet the needs of modern construction projects. Therefore, for businesses planning to invest in UPVC Window manufacturing, selecting the right equipment and maintaining a systematic production flow are essential to achieving long-term success.

At Jinan Better Machinery Co., Ltd, we have been deeply involved in the UPVC door and window machinery industry for nearly 30 years. Over time, we have accumulated rich experience and developed mature production technologies. Moreover, we remain committed to continuous innovation and product optimization, consistently improving the precision, stability, and intelligence of our equipment. We proudly provide global customers with efficient, durable, and easy-to-operate UPVC Window Machines. Thanks to excellent product quality and professional service, our machines are sold worldwide and have earned the deep trust and high praise of both domestic and international customers.

If you are interested in, please feel free to contact us!

Email: info@windoormachine.com

WhatsApp: +86 18354168033