How to Make Aluminum Windows

Aluminum windows have become increasingly popular due to their durability, sleek design, and energy efficiency. Whether for residential or commercial applications, aluminum windows offer a perfect blend of modern aesthetics and long-lasting performance. In this article, we (Jinan Better Machinery) will explore the key advantages of aluminum windows, walk you through the complete manufacturing process, highlight the essential machinery involved, and share practical maintenance tips to help ensure optimal window performance for years to come.

Advantages of Aluminum Windows

Aluminum windows offer a wide range of benefits that make them a popular choice for both residential and commercial buildings:

- Exceptional Durability: Aluminum is highly resistant to corrosion, extreme weather conditions, and warping, ensuring a long service life with minimal degradation over time.

- Low Maintenance: Unlike wood or steel windows, aluminum frames require little upkeep. They don’t rust, rot, or need frequent repainting, which significantly reduces long-term maintenance costs.

- Modern Aesthetic & Design Flexibility: With slim frames and a clean, contemporary look, aluminum windows can accommodate large glass panels, allowing more natural light and enhancing architectural appeal.

- Energy Efficiency: When combined with thermal break technology and insulated glazing, aluminum windows help reduce heat transfer, improving energy savings and indoor comfort.

- Environmentally Friendly: Aluminum is 100% recyclable and can be reused repeatedly without losing quality, making it a sustainable and eco-conscious building material.

- Security & Strength: The inherent strength of aluminum allows for enhanced security features and larger frame sizes without compromising structural integrity.

- Weatherproof Performance: Aluminum windows offer excellent resistance to wind, rain, and UV exposure, making them suitable for a wide range of climates.

With these advantages, aluminum windows continue to be a smart, stylish, and sustainable solution for modern construction needs.

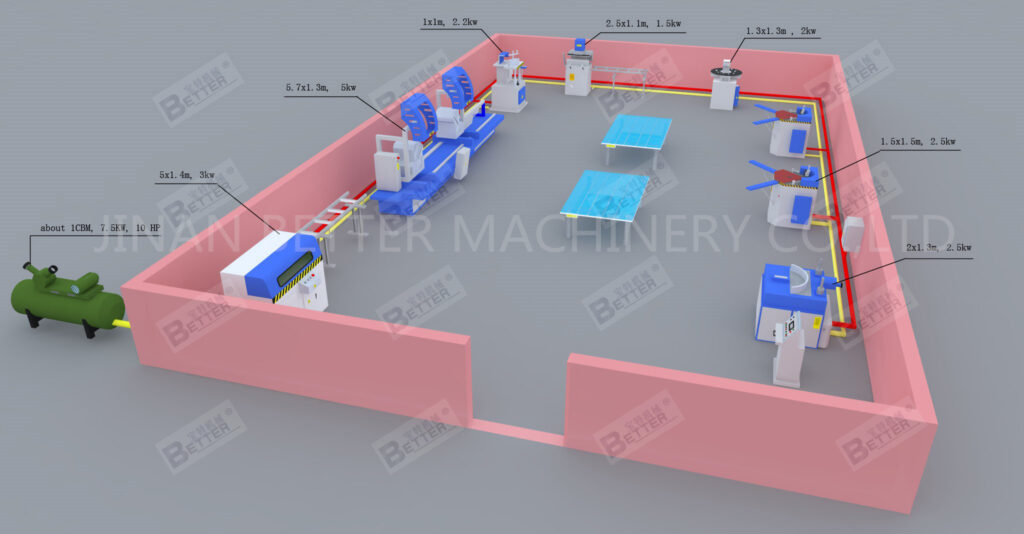

Steps to Make Aluminum Windows & Required Machines

Manufacturing aluminum windows involves several key steps, each requiring specific machines and tools to ensure precision, efficiency, and quality.

Step 1. Profile Cutting

Purpose: Precisely cut aluminum profiles to size.

Machine: Aluminum Profile Cutting Saw

Types:

- Single Head Cutting Saw: Suitable for basic cuts.

- Double Head Cutting Saw: Offers higher efficiency and precision.

- CNC Cutting Saw: Enables automatic cutting, ideal for batch production.

Base on your requirements, you can choose single head cutting machine or double head cutting machine with different automation levels. For example, if you need single head saw, you can connect it with the digital measuring table (Automatic sizing rack) to cur profiles with better precision and efficiency. If you need a double head saw, you can choose to use CNC control system type or digital display type to improve the automation.

Step 2. Hardware Hole Milling & Punching

Purpose: Mill or punch various holes, such as lock hole and handle hole.

Machine: Copy Router Milling Machine & Punching Machine (Punching machine can greatly improve the work efficiency)

Copy Router Milling Machine Types:

- Single Head Copy Router: Suitable for small workshop basic hole milling needs.

- CNC Copy Router: More intelligent model to mill various holes, reduce manual operation, achieve more accurate and precise results.

Punching Machine Types:

- Pneumatic Punching Machine: Basic type to punch casement window holes.

- Hydraulic Punching Machine: Big power and more stable to punch holes. Hydraulic punching machine with rotatable workbench can contain 6 molds maximumly, greatly improving the work efficiency.

Step 3. End Milling for Mullion Profile

Purpose: Milling the end face, step face and end face groove of the mullion profile. It is used for mullion connection with the frame.

Machine: End Milling Machine

Type: Manual, semi-automatic, and CNC end milling machines.

Step 4. Corner Connector Cutting

Purpose: Cutting the corner connector that be used for connecting frame corners.

Machine: Automatic feeding aluminum cutting machine

Type: Semi-automatic, CNC aluminum cutting saw

Corner connector cutting saw is a 90 degree cutting saw with automatic feeding function. It can cut a material without any supervision. Therefore, it can be used in various industries, not only aluminum window production.

Step 5. Corner Crimping / Corner Screwing

Purpose: Join frame corners firmly to form frames/sashes.

Machine: Aluminum Window Corner Crimping Machine / Corner Screwing Machine

- Corner Crimping Machine Type: Single Head Corner Crimping Machine, Aluminum Window Crimping Line

- Corner Screwing Machine Type: CNC corner screwing machine with glue injection function

Step 6. Aluminum Bead Cutting

Purpose: The aluminum glazing bead is installed on the inside of the window or door leaf to fix the glass firmly in the aluminum profile frame.

Machine: Bluetooth Bead Cutting Machine

Types: Bluetooth Bead Cutting Saw, CNC Bluetooth Bead Cutting Machine, Automatic feeding CNC Bluetooth Cutting Machine

Step 7. Arch Bending

Purpose: bending arc shape for special arch windows and doors

Machine: Aluminum bending machine

Types: CNC bending machine, aluminum bending machine with drawing importing function……

Step 8. Glass Installation

Purpose: Produce and install insulating glass units.

Machine: Insulating Glass Production Line machines

Components:

- Glass washing & drying machine

- Spacer bar bending machine

- Desiccant Filling Machine

- Butyl Extruder Machine

Step 9. Assembling & Final Adjustment

Use tools and jigs for accurate assembly. And aslo, apply sealing strips, accessories, and handles.

How to Maintain Aluminum Windows

- Proper care ensures longevity.

- Clean frames regularly with mild detergent to prevent dirt buildup.

- Lubricate hinges and locks every 6–12 months.

- Inspect seals and gaskets annually and replace if damaged.

- Avoid abrasive cleaners that may scratch the aluminum surface or degrade the anodized or powder-coated finish.

Conclusion

Aluminum windows are a smart choice for modern buildings, offering strength, style, and energy efficiency. By understanding the manufacturing process and using the right equipment, you can ensure quality and performance. Proper maintenance also extends the life of your windows.

Contact Us

Looking for high-quality aluminum window machines? Jinan Better Machinery specializes in aluminum window machines, UPVC window machines, and insulating glass production lines. Contact us today to get a quote or technical support:

- Website: https://windoormachine.com/

- Email: info@windoormachine.com

- WhatsApp: +86 18354168033